Improving on-the-spot decision-making through NIR Spectroscopy

The way to circularity starts with sorting

One of the major challenges on our path towards a circular economy is the lack of high-quality recycling worldwide. A key piece to establishing circularity lies in the first step of the recycling process: a clean on-the-spot sorting of plastic waste.

By enabling flexible plastic identification at the push of a button, our solution ensures clean plastics waste streams across recycling facilities worldwide.

And followed by enabling flexible plastic identification

We bring the added value that is most useful to you: Reliable identification of a variety of plastic types. For this purpose, we equip you with a powerful tool for on-site analysis of diverse plastic types. Our Mobile NIR Spectroscopy Solution combines mobile hardware, data analysis, and material expertise to identify and distinguish a broad range of plastic types to support the path toward a circular economy.

Our solution at a glance

We integrated a proven technology into a handheld solution for remote analysis, consisting of:

- a high-performance NIR spectrometer that detects a broad range of plastic types.

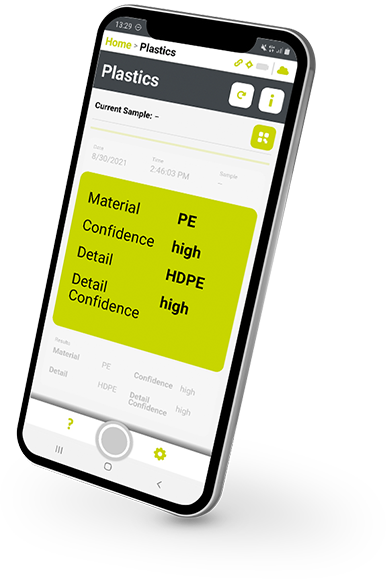

- an easy-to-use app backed by advanced cloud data analysis for fast results even without an internet connection.

- a customer portal to manage results, download reports, and export data.

- A detailed support portal provides comprehensive answers to your questions. Our expert support team is also on hand to help.

How our on-the-spot solution adds value to the recycling process

- Watch our clip for an example of we enable customers to enhance their incoming and outgoing quality checks.

A powerful combination of mobile hardware, data analysis, and material expertise

![Product Image NIR Spectrometer [Hardware]](/media/product-image-nir-spectrometer_upright.png)

Our device is

- Easy-to-use

Our handheld device offers intuitive handling and is operated at the press of only one button. - Reliable

You can rely on the performance of your device – even under temperature or mechanical stress, and without an internet connection. - Convenient

Our Bluetooth-connected device enables you to transfer data immediately and effortless. - Scalable

In our production facility, we manufacture high-quality IR chips that are assembled in Austria/Germany.

Our offer for the reliable identification of a variety of plastics

Our hardware combined with the available calibration modules Plastics Pack, Plastics Pack PLUS and Plastics Pack MAX will bring the power of mobile NIR Spectroscopy to the palm of your hand. The fast, easy, and flexible identification of diverse plastic types including our mobile spectrometer, app, and customer portal takes place in an ideal plug-and-play solution for post-consumer plastic waste recycling facilities or all kinds of industries on a path toward a circular economy.

Get in touch with us

If you have any questions regarding our solution or would like to arrange an appointment for a product demo, you can reach us via our contact form. Also, feel free to reach out directly to our experts.

For more details, please download our information material!

Are you interested in directly collaborating with us?

By working together, we explore opportunities, share knowledge, and benefit from each other. Find out the best trinamiX partnership model matching your business needs by answering only a few questions.

Sales Contact trinamiX

Global Sales Contact trinamiX